Generator Performance

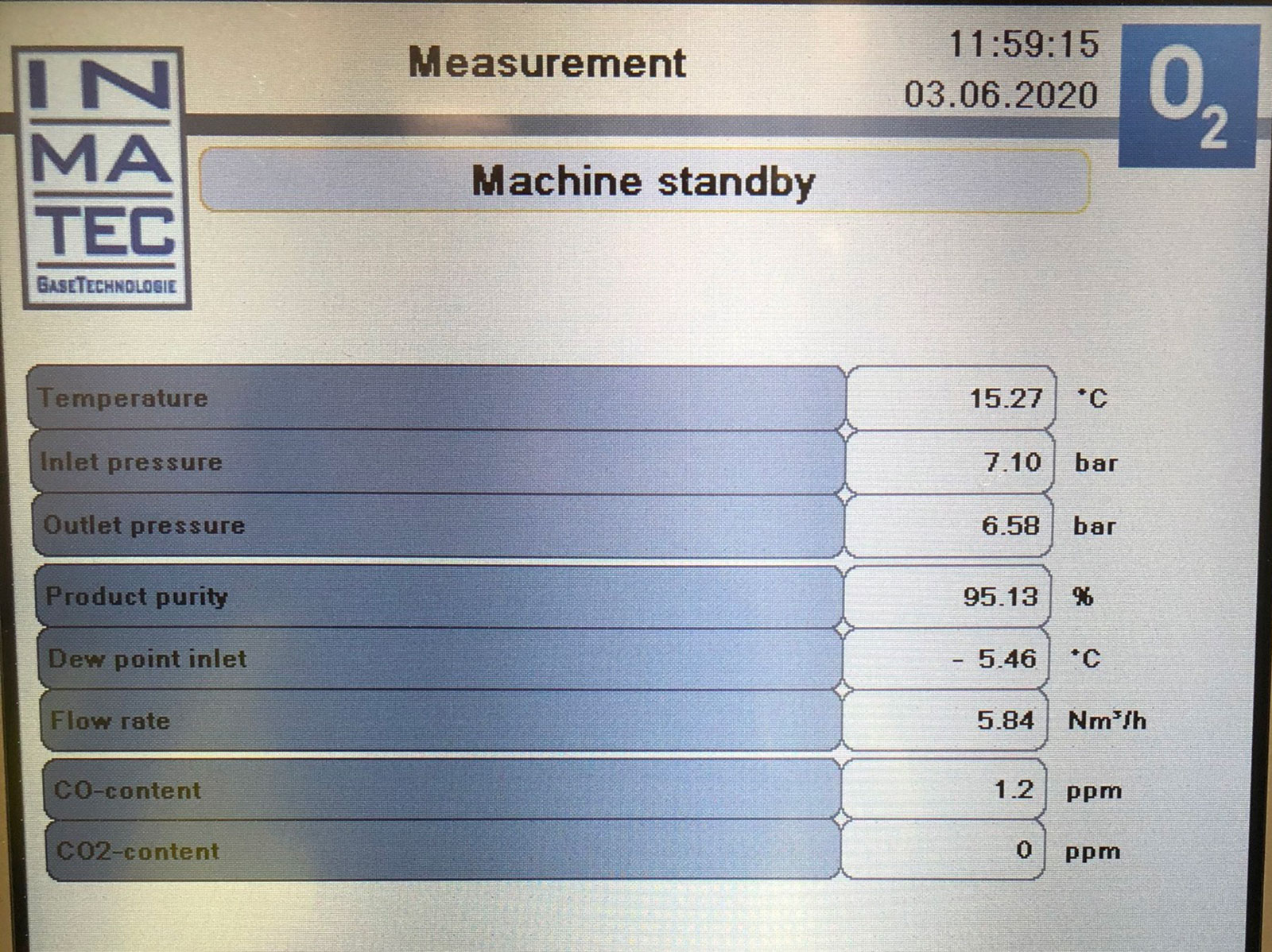

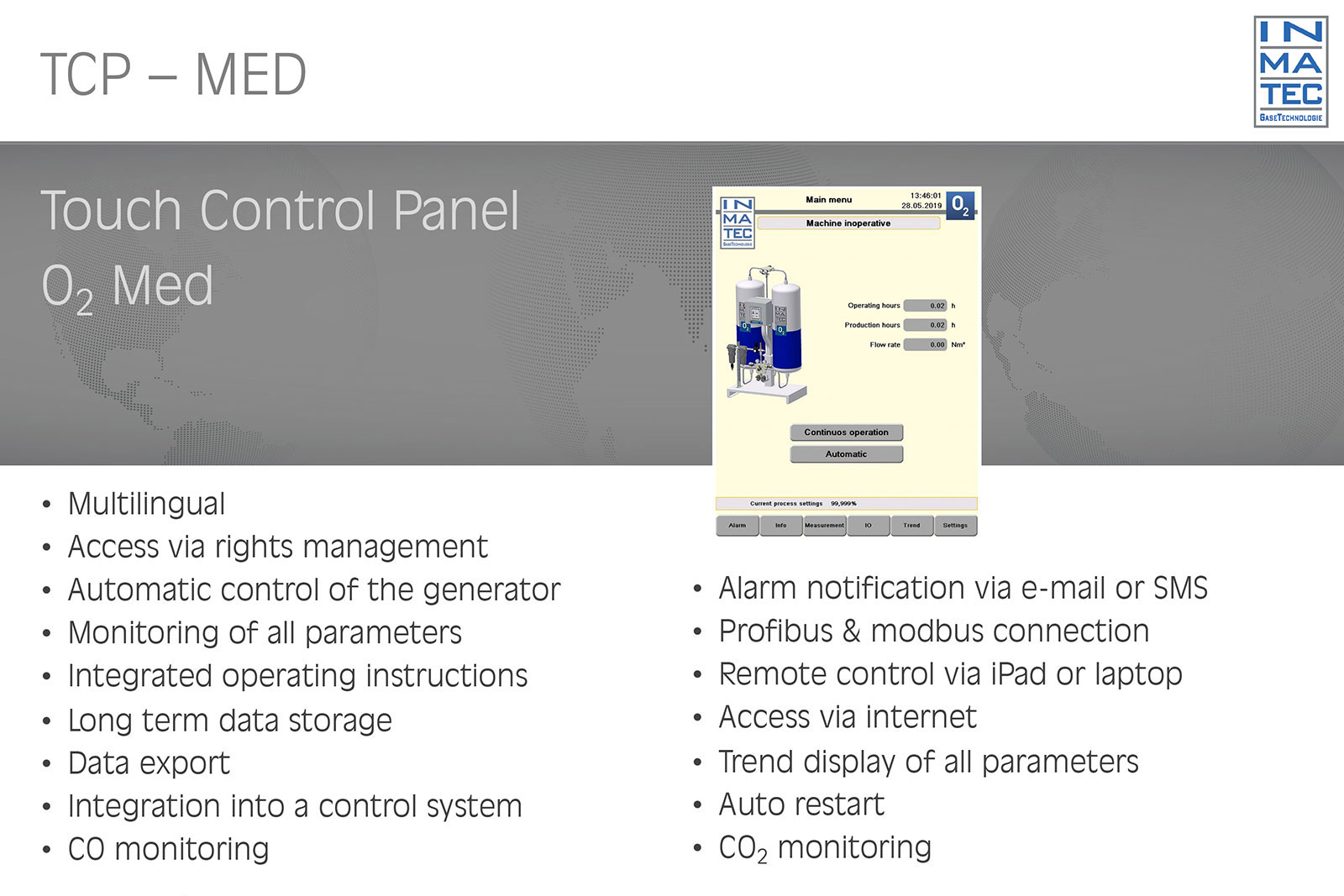

All our N2 and O2 system come with state of the art remote control technology to link the generation systems to PCM via INMATEC’s control centre.

This enables us to monitor all the functions and parameters of your nitrogen or oxygen generators and access your systems online as required, helping you avoid production downtimes, and even more importantly, economic loss.

Log in details can be provided to the end user to monitor remotely with alarm features being emailed in the event of a performance alert.

Full performance data logging is held within the generator controller and weekly performance reports emailed to registered email addresses.

For us, “big data” is more than just an empty phrase. Via our remote monitoring box, we record critical production data in real time and then use analyses and algorithms to provide accurate forecasts and recommendations. Offering increased safety and convenience with a commercial advantage.

REGIONAL PARTNERS OF OXYSYSTEMS – MANUFACTURERS OF MEDICAL OXYGEN MONITORING, CONTROLS AND OIL FREE BOOSTERS