Nitrogen and Oxygen Generation

Nitrogen and Oxygen gas applications traditionally obtain gas through deliveries of liquid which is evaporated off into a useable gas or supplied by high pressure gas bottles. Nitrogen and Oxygen generation is becoming a more practical and cost effective option for industry and medical applications, as well as providing a greener lower carbon footprint answer.

PCM will consult and guide you through the most efficient gas generation options for your application and expected cost comparisons over traditional gas supplies. Savings of up to 80% have been achieved on previous projects with the major advantage of having GAS ON DEMAND.

No waiting on liquid deliveries, or loses due to high pressure liquid vent off, No processing of gas delivery orders and with all our systems having a full performance logging feature, you will be able to see how your equipment is performing, even logging in remotely while off site.

Manufacture and Installation

PCM are sales and service partners for INMATEC Gas generation products in Northern Ireland and Scotland. We are able to offer a comprehensive range of generators to meet all demands and sizes from standard units to special builds.

The INAMTEC range can produce nitrogen with a purity of 95% to 99.999% (5.0) and 99.9999% (6.0) at quantities of between 0.50 and 10,000.00 Nm³/h. The Oxygen generators offer a supply with a purity of up to 95% and quantities between 0.5 and 500 Nm³/h.

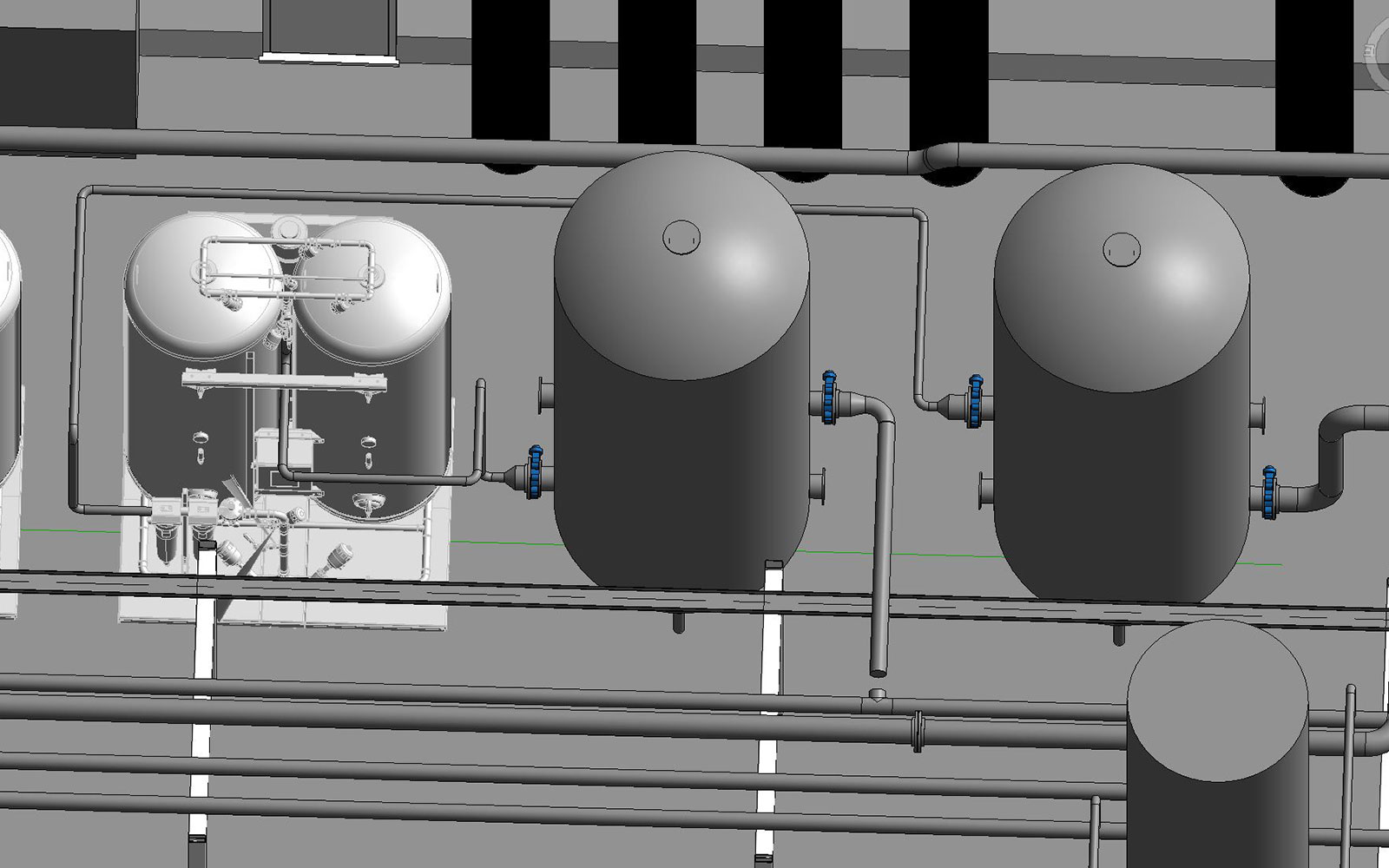

PCM provide a turnkey manufactured package to include compressed air, filtration, N2 /O2 Gas generator unit, controls, boosted pressures, storage and plant room / containerised builds.

High pressure bottle fill stations are available to remove the need for deliveries by road, where N2 and O2 site users can produce their own gas and constantly replenish as they use. This also has the added benefit of a lower carbon footprint and uninterrupted gas supply.

Plant rooms permit larger systems to be installed and provide a bespoke design and capacity better suited for sites where containerised mobility is not required.

Service and Maintenance

PCM Excel in the quality of our service cover – all our SLA’s (Service Level Agreements) are fully transparent, detailing the serviceable components at the correct service intervals.

We would consult with you – the end user – ahead of any SLA being put in place and once agreed we would commit to holding serviceable parts in stock ahead of your scheduled interval.

All our services will be by fully trained service engineers using only original OEM components and in keeping with your manufacturer’s warranty – which can often be extended such is the quality of our service cover.

Our SLA’s and regular servicing will keep your N2 and O2 gas generators working to the highest standards, ensuring reliability and performance as standard.